Introduction

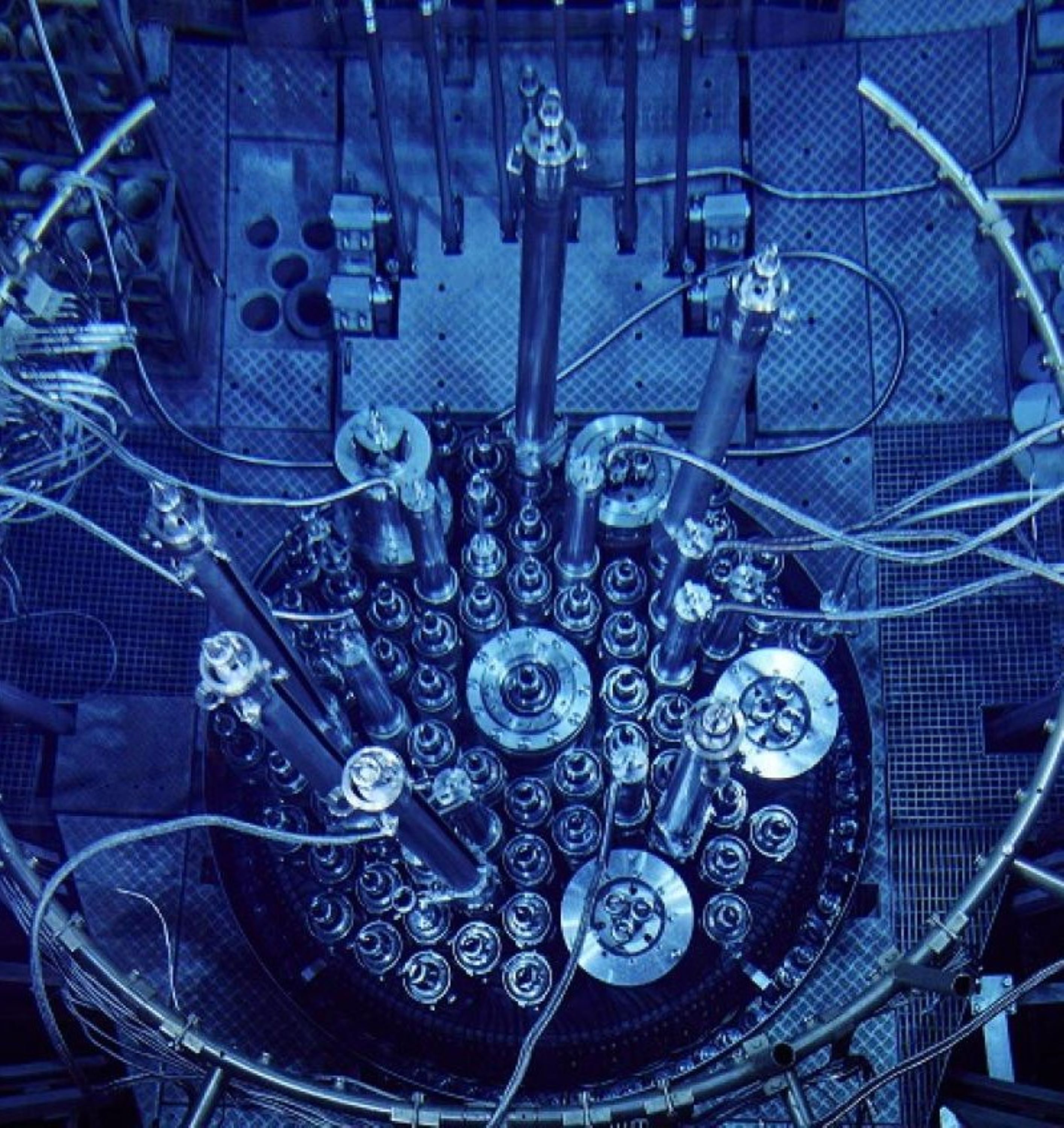

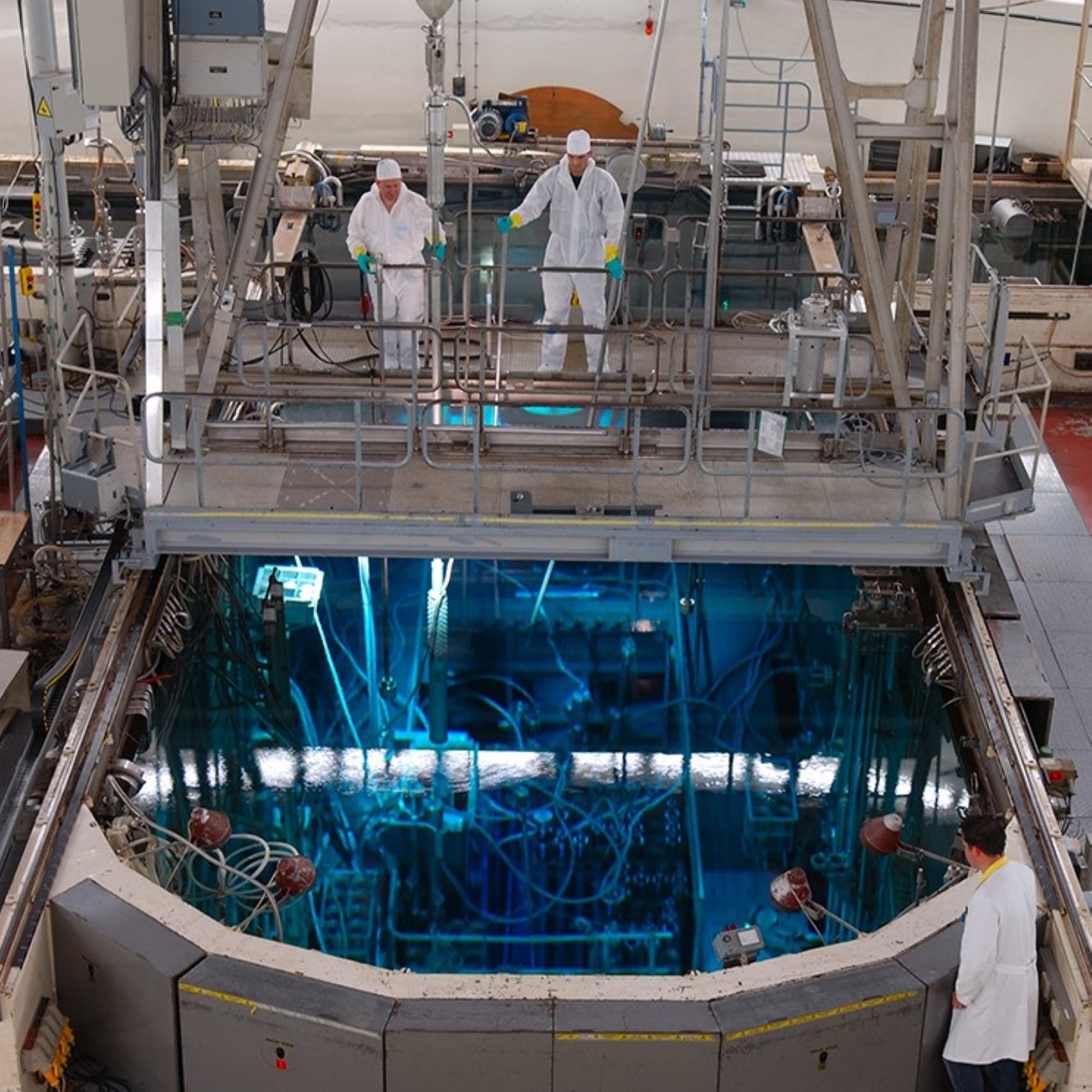

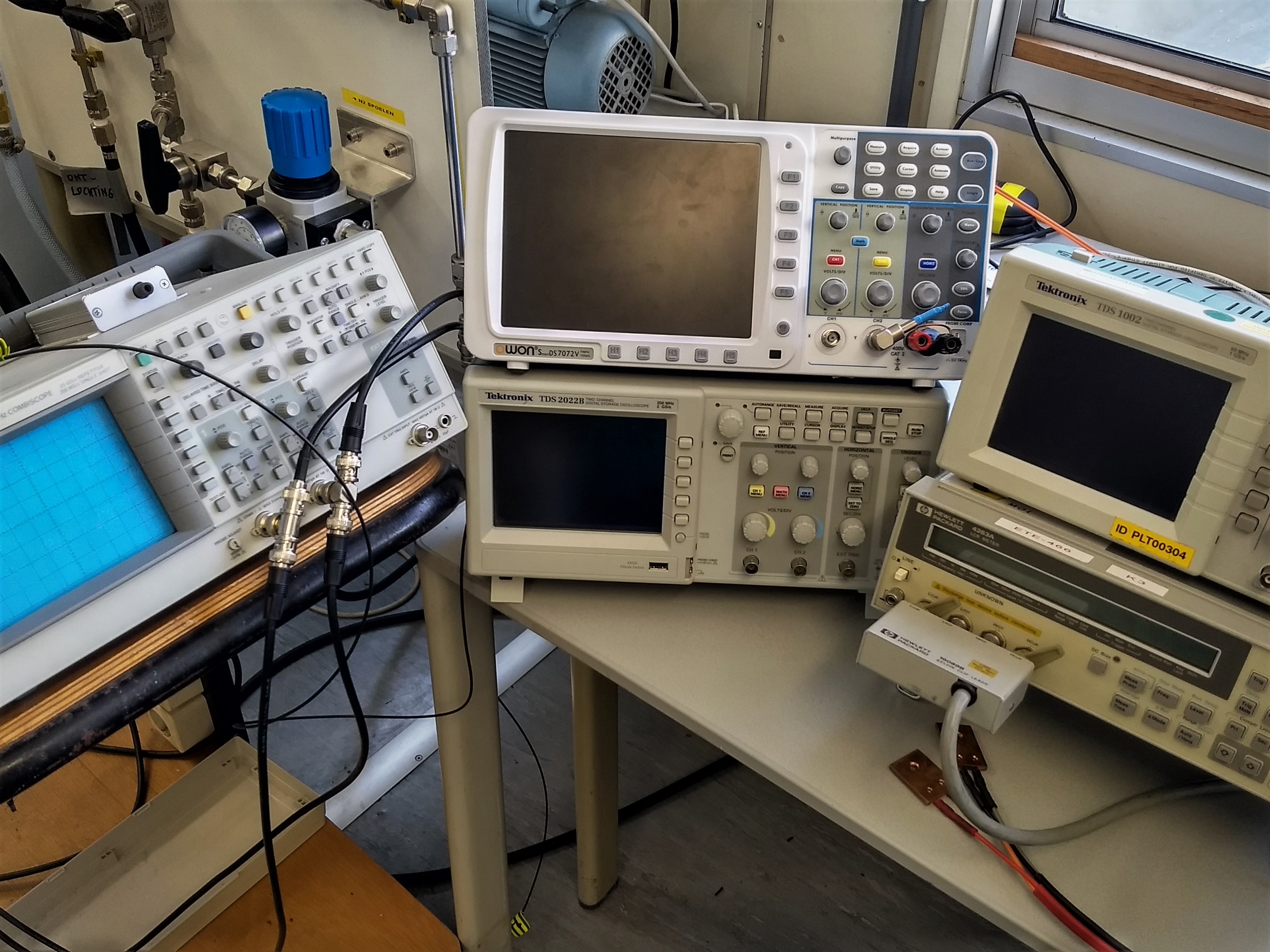

Hi, my name is Jord Peeters (°1999). I’m an industrial engineer with a great passion for renewable energy and innovative research. June 2021 I graduated at the university of KU-Leuven in Belgium and started my first job at the Flemish Institute for Technological Research (VITO). There I did research on Electro Pulse Drilling, a new kind of drilling technique that uses electrical energy instead of mechanical force to achieve rock breaking. Nowadays I work as a project engineer at the Belgian Nuclear Research Centre (SCK CEN) in Mol. My aim is to improve and renovate the classical and nuclear measuring instrumentation by replacing old pneumatic measurement chains with modern 4-20 mA electrical circuits. I’m responsible for making the nuclear power plant (BR2) as energy efficient as possible. Replacing old heavy motors with modern frequency controlled AC motors. I’m interested in a permanent position with an international company that works with renewable energy such as solar power, wind turbines, hydrogen generators and nuclear power. Or an engineering position in the research and development department of a sustainable company. I’m a driven person who is not afraid of big challenges. I’m a great team player and a naturel leader. My motto in life is “perseverance is my superpower”. I will always find a solution.